TL;DR

• Developing new battery technologies for electric vehicles (EVs) is a lengthy process, often taking decades due to extensive research, testing, and scaling.

• Battery swap systems offer a practical solution to accelerate the adoption of these innovations by allowing gradual integration into existing vehicles.

• This approach enables drivers to benefit from advancements without the need for complete vehicle redesigns.

The journey from laboratory breakthroughs to consumer-ready battery technologies is lengthy. Strategies like battery swap systems can help bridge the gap. By facilitating the gradual integration of new chemistries into existing EVs, these systems accelerate adoption and mitigate risks associated with material shortages and evolving regulations.

As the EV industry continues to evolve, embracing such innovative approaches will be key to bringing cutting-edge battery technologies to consumers more efficiently.

The EV industry is abuzz with advancements like:

- Sodium-ion batteries use plentiful sodium resources, which can reduce the need for scarce materials like lithium and cobalt. They also provide better thermal stability, enhancing safety in EVs.

- Magnesium-ion batteries are being studied for their potential to deliver higher energy densities and safer chemistries compared to current lithium-ion batteries. Research into quasi-solid-state magnesium-ion batteries has shown promise in achieving these goals.

- Solid-state batteries replace flammable liquid electrolytes with solid materials, aiming to improve safety and energy density. Recent advancements include the development of anode-free, sodium-based solid-state batteries, which can charge quickly and last for several hundred cycles.

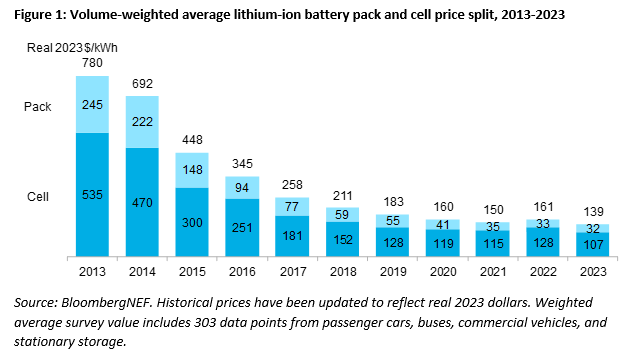

Yet, these innovations often require decades to become commercially viable and affordable for consumers.

The Long Road to Market

Developing new battery technologies involves extensive research, rigorous testing, and significant investment. After initial breakthroughs in the lab, these technologies must undergo scaling for mass production, ensuring they meet safety standards and performance expectations. This process is time-consuming and costly, contributing to the lengthy timelines before consumers see these innovations in their vehicles.

Historical Context: Lithium-Ion Batteries

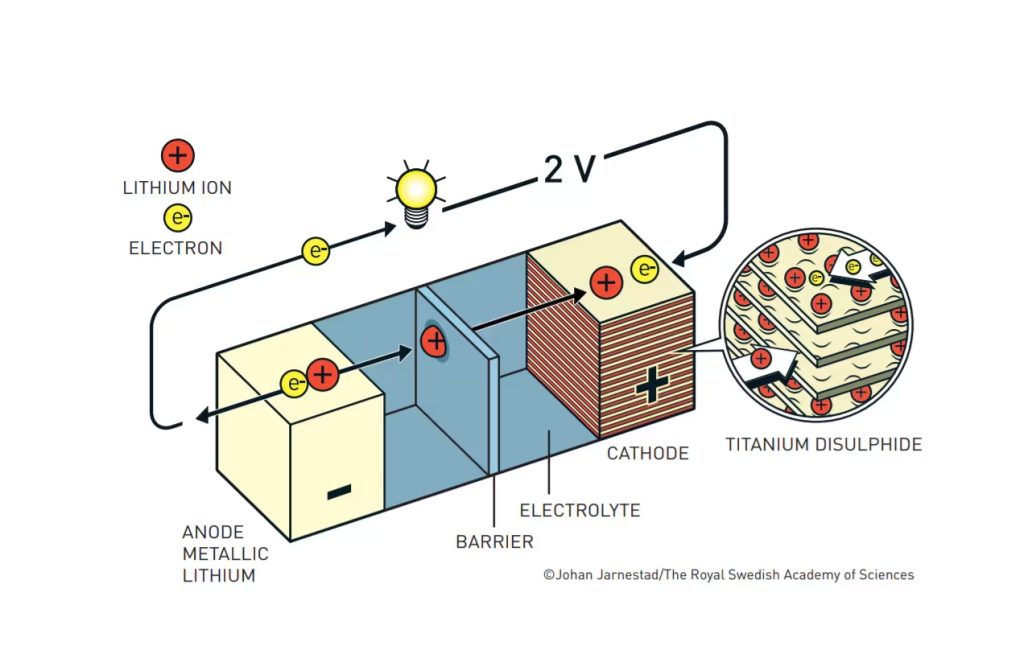

The development of lithium-ion batteries began in the 1970s. British chemist M. Stanley Whittingham proposed the concept while working at Exxon. In 1980, John B. Goodenough and his team discovered lithium cobalt oxide as a cathode material, which became a foundation for future batteries. By 1991, Sony commercialized the first lithium-ion battery, marking a significant milestone in portable energy storage.

Source: Lithium Ion Battery – History – Advancing Materials (Thermo Fisher)

These batteries have since become integral to various applications, including electric vehicles, due to their high energy density and rechargeability. The journey from initial research to widespread adoption underscores the extensive time, about 3 decades, and effort required to bring new battery technologies to market.

Sources:

- Study reveals plunge in lithium-ion battery costs – David L. Chandler | MIT News Office

- Lithium-Ion Battery Pack Prices Hit Record Low of $139/kWh | BloombergNEF

- A Behind the Scenes Take on Lithium-ion Battery Prices | BloombergNEF

Challenges Facing Emerging Technologies

New battery types like solid-state and sodium-ion batteries face similar hurdles. Solid-state batteries, for instance, aim to replace flammable liquid electrolytes with solid materials, enhancing safety and energy density. However, despite significant investment, they are still not widely available.

Accelerating Adoption Through EV Battery Swap Systems

EV Battery Swap systems offer a practical solution to expedite the integration of new battery technologies. These systems are designed to work with various battery types, allowing manufacturers to introduce advanced or experimental batteries into existing vehicles without major redesigns. This approach enables gradual adoption, ensuring fleets remain current without being tied to outdated systems.

(Image credits: Long Road to Better Taxi Service in Hong Kong – CUHK Business School)

This method is comparable to how London’s black cabs or Hong Kong’s taxis maintain consistent vehicle designs over the years while updating components as needed. Drivers continue using familiar vehicles, benefiting from advancements in battery technology without the need for entirely new models.

Conclusion

While the journey from laboratory breakthroughs to consumer-ready battery technologies is lengthy, strategies like battery swap systems can help bridge the gap. By facilitating the gradual integration of new chemistries into existing EVs, these systems accelerate adoption and mitigate risks associated with material shortages and evolving regulations.

As the EV industry continues to evolve, embracing such innovative approaches will be key to bringing cutting-edge battery technologies to consumers more efficiently.