Discover

Our AI-powered EV battery swap system is the most advanced and affordable solution for high-mileage fleet operators, engineered to significantly reduce the Total Cost of Ownership (TCO).

Compatible with 80% of Battery Electric Vehicles (BEVs) and open to all EV manufacturers, it ensures seamless integration across diverse platforms.

This intelligent system is the most cost-effective way to move billions of people and goods sustainably, leveraging renewable energy to drive a smarter and greener future.

Advantages

Lower cost for buyers

The cost of purchase is reduced by excluding the battery. Providing the Battery as a Service (BaaS) is also a good business model for energy partners.

World 1st Multi-standards

More battery pack sizes for different electric vehicles.

~3X battery lifespan

By charging at the right temperature and speed, the battery pack last up to 3X longer compared to Fast Charging.

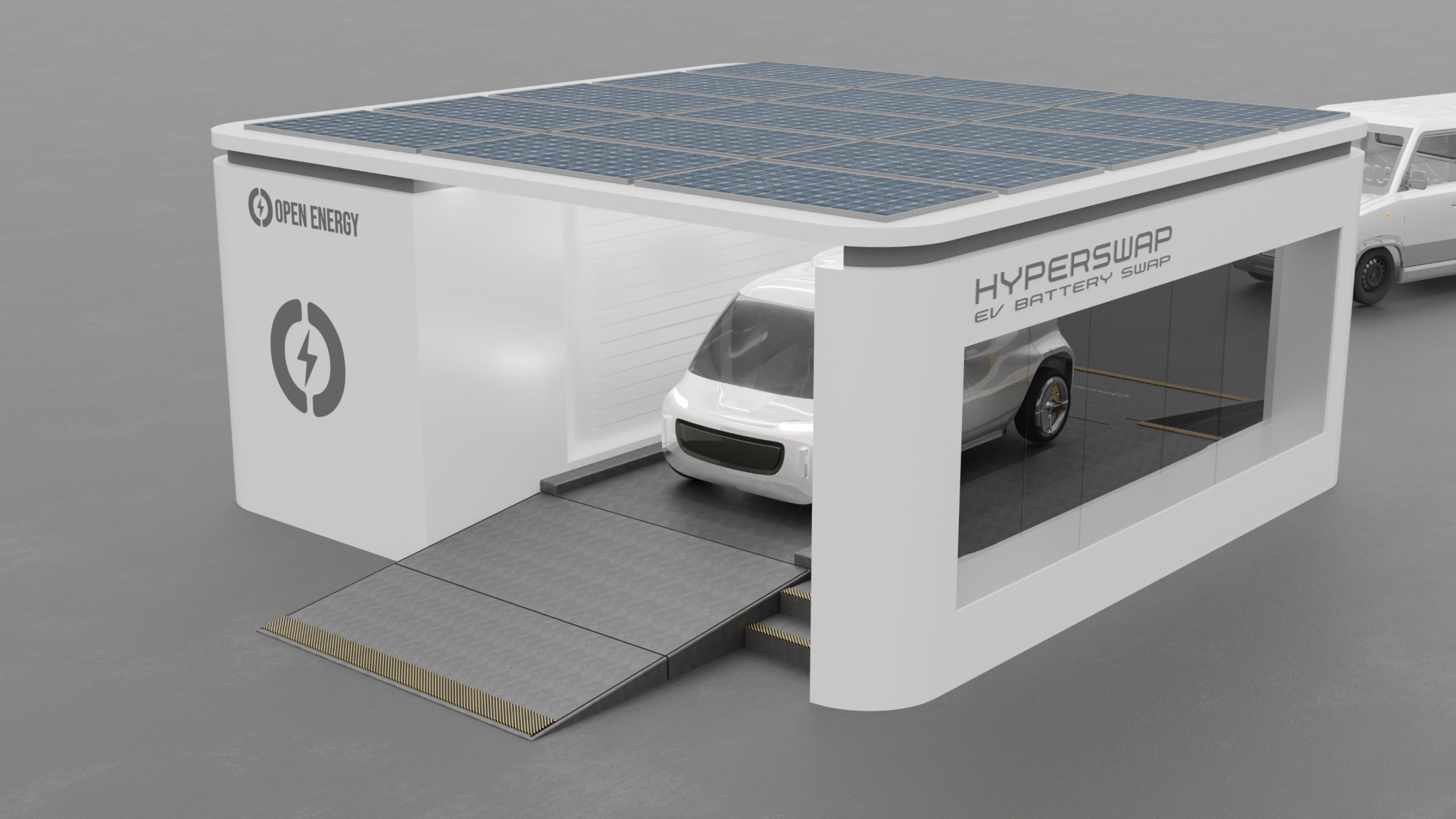

How does the HyperSwap work?

The HyperSwap system operates on a straightforward principle: an empty battery is removed from an EV and replaced with a fully charged one in approximately three minutes. The empty battery is transported inside the HyperSwap station, where it undergoes an immediate health check to ensure its integrity. The station then adjusts the battery’s temperature, recreating optimal lab conditions, before initiating smart adaptive charging. This intelligent process tailors the charging cycle to the battery’s specific needs, promoting optimal performance and significantly extending its lifespan.

The HyperSwap station is connected to the grid, allowing it to act as a power source during peak hours, supporting grid stability. It is a highly automated, compact, and safe system, designed to accommodate various battery types and to be easily replicated across multiple locations.

To ensure optimal safety and performance, the system performs a comprehensive battery health check during each swap. This process evaluates the integrity of the battery pack and all individual cells, helping to prevent potential issues like the overheating problems that can lead to EV fires.

Steps:

- Positioning and aligning the vehicle with the HyperSwap platform.

- Aligning the mechanical system beneath the vehicle.

- Unlocking and releasing the empty battery from the vehicle.

- Transporting the empty battery to the HyperSwap station.

- Empty battery “health check”.

- Placing the empty battery on the HyperSwap station for charging.

- Positioning and locking the new battery onto the vehicle.

- Performing a system check of the high-voltage connections.

- Releasing the vehicle and retracting the swapping mechanism.

Effortless EV Adaptation

Unlike competitors who require EV manufacturers to conform to their specific battery pack standards, our system adapts to existing designs, offering unmatched flexibility and compatibility. At the core of this solution is our innovative “space frame,” a near plug-and-play installation positioned between the chassis and the battery pack. This design allows seamless integration with diverse battery types without disrupting manufacturing or assembly lines.

Our team provides full support, including pre-feasibility and feasibility studies, space frame engineering and installation, battery pack system updates, and manufacturing line assistance. Authorized companies specializing in fleet customizations, such as cold chain transport modifications, can easily handle the space frame installation. This ensures EVs are effortlessly tailored for advanced energy solutions while preserving existing workflows and operational efficiency.

Problem

Electric Vehicles (EVs) for Mobility as a Service (MaaS) and Logistics are on a collision course with a series of massive challenges that threaten their viability. The soaring Total Cost of Ownership (TCO), driven by expensive batteries with limited lifespans and warranties, deters widespread adoption. Heavy battery packs reduce performance and increase energy consumption, adding further strain. Charging infrastructure adds to the storm: slow charging means vehicles sit idle for hours, while fast charging rapidly degrades batteries at a chemical level, reducing lifespan and raising serious safety concerns like overheating and even fire risks. The situation is compounded by the astronomical costs of building charging stations, upgrading real estate, and managing simultaneous charging demands, which could destabilize the grid and cause widespread outages.

3 main problems

1. Total Cost of Ownership (TCO)

Battery cost, life, warranty

→ low adoption of EV

Battery weight → bad performance consumption

2. Charging & operational time

Level 1 – 2 slow charging

→ long time car inactivity

Level 3 Fast charging

→ battery life cycle reduction and safety issues

3. Energy Infrastructure

High costs: Stations, Infrastructure and Real Estate

Limited availability → Range anxiety

Simultaneous charging

→ Potential GRID overload

Solution

The challenges of transitioning to electric vehicles—spanning high costs, downtime, grid instability, and safety concerns—require a solution that not only addresses immediate problems but also adapts to the evolving energy landscape. Our approach incorporates AI-driven energy orchestration to create a safer, more efficient, and sustainable system. Batteries are charged under optimal conditions, with precise control of temperature and speed, extending their lifespan by up to three times compared to fast charging (more info here).

AI continuously analyzes and balances the energy demands of HyperSwap stations, grid capacity, fleet requirements, and the fluctuating availability of renewable energy sources. This ensures optimal energy allocation, preventing grid overload while adapting dynamically as EV adoption grows. Vehicles achieve full battery capacity in approximately three minutes, keeping downtime minimal and operations smooth.

Our infrastructure is designed for scalability, requiring minimal real estate and reducing costs, while asynchronous charging alleviates peak load stresses and stabilizes the grid. By integrating AI and sustainable practices, this system evolves alongside the increasing energy demands of an electrified world, creating a resilient and adaptable foundation for the future of transportation.

1. Total Cost of Ownership (TCO)

~3X Battery lifespan → higher adoption of EV

Less Battery weight → better performance consumption

2. Charging & operational time

Full Battery Capacity in 2.5 minutes

Batteries are charged in the stations at the right temperature and speed (up to 3X longevity)

3. Energy Infrastructure

Low cost setup, and minimum Real Estate impact

High availability → No range anxiety

Asynchronous charging → low peaks & stabilize the GRID

Integration

HyperSwap is a transformative integration of renewable energy, made indispensable by the complexities of modern energy demands. Orchestrated by AI, it dynamically synchronizes all critical assets—HyperSwap stations, grid capacity, fluctuating renewable energy sources, and the ever-growing energy needs of EV fleets. This system adapts in real-time, ensuring seamless alignment with the evolving landscape of electrification. Batteries in HyperSwap stations act as a powerful energy buffer, storing surplus energy from solar, wind, and hydro sources, and redistributing it to the grid during peak demand through advanced bi-directional technology. By leveraging energy arbitrage, charging during low-cost, off-peak hours and selling during high-demand periods, it maximizes financial and operational efficiency. In markets like Italy, where grid demand can see up to a 9x price delta, this adaptability is essential. This AI-driven ecosystem is the only way to achieve optimal efficiency, enabling sustainable electrification at scale while stabilizing the grid and reducing costs.

Competitive Comparison

HyperSwap’s innovative Space Frame and HyperLock System redefine EV battery maintenance, offering manufacturers a seamless, cost-effective solution. The Space Frame acts as a universal interface between battery packs and vehicle chassis, enabling tool-free swaps while maintaining compatibility with existing production lines. The HyperLock System, engineered with precision from automotive, aerospace, and motorsport technologies, ensures secure, rapid battery attachment and detachment. Together, these features simplify maintenance processes, reduce downtime to minutes, and lower infrastructure costs—even for fleets or users not reliant on daily battery swaps. By streamlining repairs, upgrades, and battery lifecycle management, this system empowers EV manufacturers to enhance operational efficiency and sustainability without compromising affordability.

Competitive Comparison

Our competitors’ solutions are significantly more expensive and still face critical durability issues. Some of their systems have caused battery packs to detach from vehicles while in motion due to unreliable locking mechanisms, posing a safety risk. On top of that, these companies require EV manufacturers to use their own proprietary battery packs, which dictates the chemistry, size, weight, and capacity of the batteries. This forces manufacturers into a one-size-fits-all approach, a major obstacle for those seeking flexibility in their EV design. Our competitors can only swap a single battery pack standard. To swap multiple types, they need to double or triple their infrastructure costs, which is inefficient and economically impractical.

Our solution, on the other hand, adapts to any battery pack standard, allowing us to swap multiple types with a single station—eliminating the need for excessive infrastructure. This is the only viable approach for scaling EV battery swapping in a cost-effective and efficient manner.

About 80% of existing electric vehicles can be adapted to use our HyperSwap system.

We offer a full range of services, including pre-feasibility studies, feasibility studies, space frame engineering and installation, battery pack engineering, system updates, and manufacturing line support. This approach offers the most cost-effective, scalable, and flexible solution for EV fleet operators.

| Competitor 1 | Competitor 2 | HyperSwap | |

| Cost of production | > $1M | ~$500K | ~$100K |

| Easy to produce in large scale | no | no | yes |

| Expensive infrastructure | yes | no | no |

| Advanced modularity | no | no | yes |

| Easily transportable | no | no | yes |

| Lifecycle management costs | high | medium | low |

| Multiple battery standards | no | no | yes |